Waterjet marble cutting is a process that allows precise and smooth cutting of marble using high pressure water. Because this technology doesn’t produce heat, it prevents thermal deformation of the marble. Waterjet is ideal for creating intricate patterns and detailed designs. The cold cutting method preserves the natural structure of the marble and doesn’t damage its aesthetic appearance. It also minimizes material waste by producing fine cuts.

What is Waterjet?

Waterjet cutting is a method of cutting materials using high-pressure water. In this method, water, often mixed with an abrasive substance (such as garnet), is sprayed at very high speed through a very fine nozzle to cut the material. Water jet can be used to cut a wide range of materials, from metals to ceramics, and from stones to marbles.

Advantages of Waterjet:

Cold Cutting: This process does not produce heat, thus avoiding thermal deformation of the material.

High Precision: This device is capable of making precise cuts and creating complex shapes with high accuracy.

Eco-Friendly: Water and abrasives are generally considered environmentally friendly materials.

Versatility: It can cut a wide range of materials.

Reduced Material Waste: The device minimizes material waste due to its ability to make precise, fine cuts.

Applications of Waterjet:

- Construction and Architecture: This product is designed for cutting stones such as marble and granite.

- Automotive and Aerospace: For precise cutting of metal components and composite materials.

- Food Industry: For the precise cutting of frozen foods and other delicate foods.

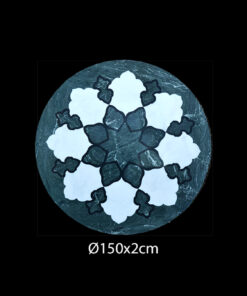

- Art and Decoration: For cutting intricate designs and detailed ornaments.

Waterjet cutting technology is a valuable asset in many industrial applications that require precision and versatility.

Principle of Waterjet Operation

A waterjet is a cutting method that uses high-pressure water. To gain insight into how a waterjet functions, let's examine the following steps:

Generating Water Pressure

The waterjet system comprises a high-pressure pump that raises the water to very high pressures (typically between 30,000 and 90,000 psi). This pressure allows the water to be sprayed in a very fine jet, which is a key advantage of this technology.

Adding Abrasive (If Necessary)

When working with materials such as metals or thick ceramics, the addition of an abrasive substance, such as garnet, to the water jet enhances the cutting ability of the water.

Cutting Nozzle

The high-pressure water and abrasive are sprayed from a very fine nozzle that performs the cutting operation. These nozzles focus the mixture of water and abrasive onto the material, allowing for precise and efficient cutting.

Cutting Process

The fine water jet strikes the material, cutting it with the help of abrasive particles. The water jet moves at a high speed over the material, performing the cutting operation. The precision of the water jet allows for intricate and detailed cuts, which are ideal for a variety of applications.

Control System

Waterjet processing machines are typically programmed with computer-aided design (CAD) files. These files define the shape to be cut and the cutting paths. The CNC (Computer Numerical Control) system precisely positions the cutting head to execute the cut with precision.

Features of Waterjet Cutting

- Cold Cutting: One of the key benefits of waterjet cutting is that it doesn’t generate heat, which is advantageous for heat-sensitive materials.

- Precision Cutting: Waterjet technology is well-suited to the creation of intricate and precise cuts. This method is ideal for the production of detailed designs and components requiring exacting tolerances.

- Material Variety: The waterjet cutting process is capable of cutting a wide range of materials, including metal, ceramics, stone, glass, plastic, and composites.

- Eco-Friendly: Waterjet cutting is a process that uses water and abrasives that are harmless to the environment.

Waterjet processing technology is a versatile and precise industrial tool with a wide range of applications.

Natural Stone Materials Cuttable with Waterjet

Waterjet can cut a wide range of natural stone materials. Here are some of these materials:

Waterjet Marble:

Marble is a natural stone that is frequently used for aesthetic and decorative purposes. It is an ideal material for cutting and is suitable for use in flooring, wall panels, and art pieces.

Waterjet Granite:

Granite is renowned for its durability and hardness, making it an ideal material for use in countertops, flooring, and outdoor applications.

Waterjet Travertine:

Preferred especially for interior and exterior cladding, travertine is a natural and rustic material with a distinctive appearance. p>

Waterjet Limestone:

Limestone is an ideal material for interior flooring and decorative elements. Its soft structure makes it simple to cut.

Waterjet Sandstone:

Sandstone is a versatile material that can be used for a variety of applications, including flooring, wall panels, and landscaping. Its natural appearance and aesthetic appeal make it a popular choice for many projects.

Waterjet Schist:

Schist, with its distinctive natural texture, is utilized for the fabrication of decorative panels and cladding.

Waterjet Basalt:

Basalt is an ideal material for paving stones, flooring, and outdoor furniture due to its hardness and durability.

Waterjet Onyx:

Onyx is a highly sought-after material for decorative purposes due to its transparent and colorful structure. It is particularly well-suited for use in lighting elements and interior cladding.

Waterjet Quartzite:

Quartzite is renowned for its hardness and durability, making it an ideal material for flooring and kitchen countertops.

Waterjet Dolomite:

Dolomite stone is a popular choice for decorative cladding and landscaping projects.

Waterjet processing technology is distinguished by its precision, smooth edges, and reduction of material waste in the cutting of natural stone materials. This technology enables the production of high-quality results in architectural and decorative projects.

Türkçe

Türkçe Deutsch

Deutsch العربية

العربية Français

Français Español

Español